Forespar's Marelon® Integrated Plumbing Systems designed to meet your boats plumbing needs. Precision moulded plumbing systems for use above and below the waterline.

Forespar's Marelon® Integrated Plumbing Systems designed to meet your boats plumbing needs. Precision moulded plumbing systems for use above and below the waterline.

This marine seavalve is made of MARELON®, a glass reinforced nylon composite. It exceeds standards for use set by the U.L. (Underwriters Laboratory) and the American Boat and Yacht Council (A.B.Y.C.). It is a complete system including thru-hull fitting, valve body, and hose connector.

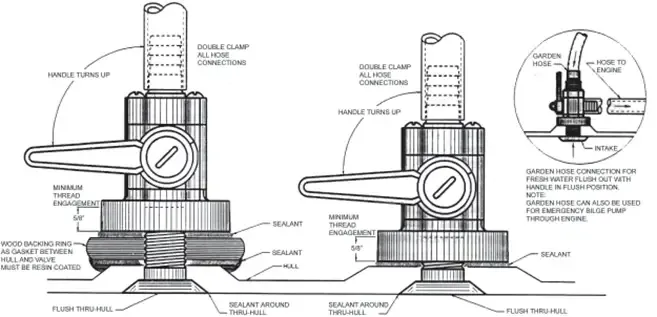

HULL OPENINGS: Prepare a clean round hole in the desired location and of the appropriate diameter for the chosen thru-hull fitting per the requirements below. For flush head thru-hull fittings only, make an external 45 deg. chamfer ¼” deep. If the recommended backing block is used, a uniform hole diameter must extend through the backing block.

½” and ¾” Thru-hull/seavalves – 1-1/8” hole

1” and 1-1/4” Thru-hull/seavalves – 1-1/2” hole

1-1/2” and 2” Thru-hull/seavalves – 2-1/8” hole

BACKING BLOCKS: A backing block or an equivalent structure molded integrally into the resin/glass hull lay-up is required for installations on all non-flat hull surfaces. This is also recommended procedure for flat surfaces as well. For wood backing blocks, white oak is a commonly used wood. There may be other suitable materials as well.

THRU-HULL FITTING LENGTH: The thru-hull fitting, when fully installed, should project beyond the internal hull/backing block surface no less than ½” and no more than 1-1/4”. Engagement of five (5) full threads will generate the full loading strength of the thru-hull/seavalve assembly, which is well in excess of the 500 pounds, required by the U.L. and A.B.Y.C. standards.

BEDDING: The thru-hull fitting’s external flange should be properly bedded when the fitting is inserted into the hull. The exposed male threads protruding from the inside of the hull should be applied with bedding material as well. The surface of the female threaded round king-nut portion of the valve, which interfaces with the internal hull surface, may well be bedded also, but it is not an absolute requirement and the loading strength will not be impaired if it is not done. Bedding compounds such as 3M’s #5200, Sikaflex or Boatlife are to be recommended as well as others that are equally suitable.

“93” SERIES THREAD FORM; The thread form used on these thru-hull fittings and king-nuts is a non-tapered buttress type of thread design. This thread form has a higher load carrying capacity, particularly for polymeric materials. Warning, a standard pipe threaded thru-hull fitting will not fit with the king-nut on these valves. For a standard pipe threaded thru-hull fitting, use our valves that have standard female pipe thread outlets instead of a king-nut base. A buttress thread design with the same amount of clearance as for a conventional pipe thread will give the impression of greater looseness. However, when the joint is taken up tight, there is a greater area of surface between threads with the buttress thread form. As with any threaded pipe assembly, Teflon® tape should be applied to the thru-hull threads for a watertight connection.

KING-NUT INSTALLATION; The fully assembled valve is threaded onto the bedding coated thru- hull fitting and tightened down by turning either the thru-hull fitting or the king-nut/valve assembly. A firm, hand-tight mount is sufficient, but if preferred, the nut can be torqued to a maximum of 12 foot-pounds. If it is desired to additionally fasten the king-nut to the backing block with screws, there is provision for such, but it is completely unnecessary. On the backside of the king-nut there are four (4) blind ¼” holes. These may be drilled through to the front side before installation to allow for round-headed screw fasteners.

VALVE CONNECTIONS: It is recommended that all hose barb connections be made using two

(2) all stainless steel hose clamps. For ½” and ¾” barbs, use 3/8” wide hose clamps. For 1” and larger connections, use ½” wide hose clamps. If the valve configuration being used has a female pipe threaded inlet, use care in the installation of the pipe nipple or elbow. Use a Teflon® pipe sealant. Be sure you are not cross threading by improper alignment and do not torque more than 12 foot-pounds.

MAINTENANCE: FORESPAR® MARELON® Thru-hull/seacocks are corrosion free and pro- vide great peace of mind in that regard. They are relatively maintenance free. Generally, lubrication is not required. What is required is to open and close them on a regular basis (4 times a year minimum). The frequency this is required is determined by two (2) things, whether the valves are routinely kept open or closed, and the rate of sea growth (weed and barnacles) in your area. If the rate of fouling is high and the valves are not actuated regularly, this build up of growth can cause any valve to turn hard or not at all. If the valve becomes stiff due to lack of use and sea growth build-up, it must be cleaned. The restriction of flow into the valve may cause harm to the machinery it serves and the valve may seize if not maintained. DO NOT DISASSEMBLE VALVE OR LOOSEN BOLTS EXCEPT IN EXTREME EMERGENCIES. All valves are factory pressure tested before shipping. Any adjustments to the bolts will void this testing and may void warranties.

All MARELON® integrated valves have a removable plug in the handle (white cap with loop). This plug is made to fit into the external thru-hull (non-screened style only). In an emergency, this plug can be placed in the thru-hull (water pressure will keep it in) and the valve disassembled while the boat is in the water. Someone must get wet, but the boat does not need to be hauled for valve repairs. By tying a lanyard to the cap, you need only get wet once.