The headstay turnbuckle should be inspected yearly and the mast should be checked for re-tuning, as wire stretches.

The headstay turnbuckle should be inspected yearly and the mast should be checked for re-tuning, as wire stretches.

If the boat is left in a warm water environment, the system should be cleaned and the lower bearing checked and flushed before leaving the boat for any length of time.

In order to inspect the headstay and Schaefer's lower bearing unit, read the Schaefer installation manual instructions thoroughly and:

-

Remove the sail. Loosen the line on the drum. Flush the line of salt

-

Support the mast properly with spare halyards

-

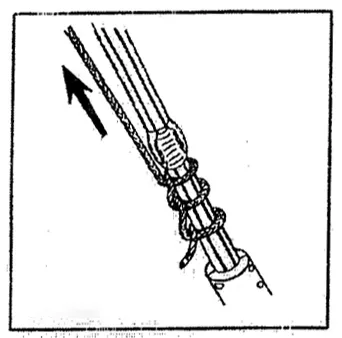

Support the extrusions with a halyard using a rolling hitch under the feeder. Tension the halyard to insure the weight of the extrusions stay in place

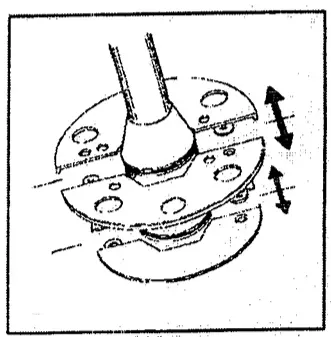

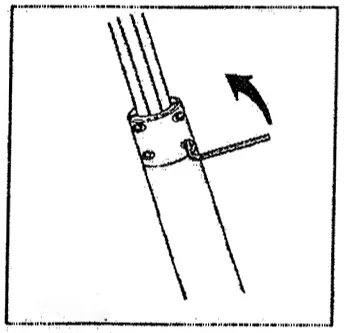

Loosen and remove the 4, 1/4" machine screws in the drum area. Clean fasteners properly

-

Back off the four Allenhead fasteners on the top of the torque tube. Lift the torque tube and inspect the turnbuckle, flush the lower bearing unit with water for a minute or two. Turn the lower bearing unit. Flush again. Use WD40 if no water is available. This should be done on a yearly basis. Lubrication is not necessary.

-

Clean the torque tube and heli coils (where fasteners are inserted) in order to wash any salt/corrosion form the system. Re-assemble using Duralac or Lanacote. Winch grease will work if no other anti-seize product is available.

-

Drum plates should be removed and cleaned

-

Wax lower portion of furler and extrusions or wipe down with mild cleaer or WD40.

-

Review Assembly Instructions