Specifying the correct block - Steve's Tips

Author: Allen Brothers Date Posted:28 June 2017

Different blocks on your boat are subject to different loads depending on the application you are using them for and where they are placed in the system.

Because each application places different demands on the bearing system in the block, there are two different types we use, in conjunction with different materials for the sheaves, each of which is suited to different applications.

Because each application places different demands on the bearing system in the block, there are two different types we use, in conjunction with different materials for the sheaves, each of which is suited to different applications.

In the plain bearing block, the sheave rotates directly on the axle, whereas a ball bearing block incorporates a sheave, rotating around a ball bearing race, which in turn rotates on an axle.

If you need a block to rotate freely under relatively low loads, then a ball bearing block will reduce the friction considerably. However, if you require a block to perform well under high static loads, then a plain bearing block may well be the better option. Recently we have developed some different sheave types which have raised the dynamic load capacity reducing friction without resorting to either a plain bearing block or high load thimble.

Before going into detail on the sheave developments themselves, it is worth explaining what happens with a ball bearing sheave when it is placed under load. Under a small load the bearings are free to roll. As the load increases the bearings compress slightly increasing friction; at the same time the sheave will also deform. Under high loads friction increases significantly and the efficiency of the bearing is lost.

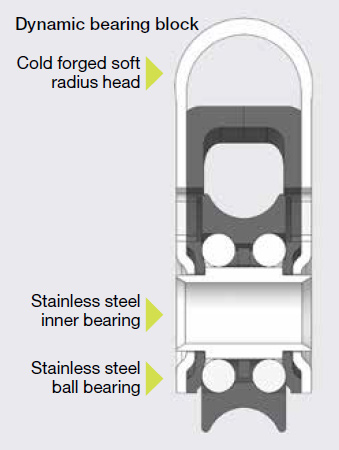

The standard sheaves used in our dynamic bearing blocks are manufactured out of an engineering grade of Nylon. The ball bearings and axle are manufactured from stainless steel, to reduce compression under load and ensure the block will have a long working life. Where possible we use a cage to separate the bearings which further reduces the friction and the weight of the block slightly, as fewer ball bearings are required.

The standard sheaves used in our dynamic bearing blocks are manufactured out of an engineering grade of Nylon. The ball bearings and axle are manufactured from stainless steel, to reduce compression under load and ensure the block will have a long working life. Where possible we use a cage to separate the bearings which further reduces the friction and the weight of the block slightly, as fewer ball bearings are required.

If we were to use Delrin ball bearings they would compress as the load on the block increased, so the block would not work as well under higher loads. It would also affect the longevity of the block as in time they will wear faster than a stainless ball bearing race.

In our highload dynamic blocks (HL) we have replaced the plastic sheave with one machined from stainless steel.

Although this doesn’t increase the ultimate strength, it does however reduce the friction in the system, as the deformation under load is dramatically reduced.

The A2030XHL block takes this concept one stage further, it was originally designed to handle the loads on the Vang.

With the XHL block we were also approaching the limit of the stainless-steel body we normally use in our dynamic blocks. With Dyneema® technology having progressed so far in recent years the obvious choice was to create a tie-on block, allowing the block to be directly loaded around the centre axle rather than having to transfer this load through the body itself. To avoid the side cheeks compressing under load these are CNC machined from solid aluminium which also offers the potential to anodise the blocks in a range of colours that makes them so distinctive. system of an International Moth, which regularly reach 600kg. To share the load, the bearing cage has been removed, meaning more ball bearings can be fitted and the internals of the sheave are lined with an aerospace bearing material which further reduces friction, when the sheave inevitably flexes under the very high loads at which this block can operate.

While both the HL and XHL blocks perform very well under the ever-increasing loads we are now able to apply with Dyneema® they are not always necessary. To reduce the friction in your purchase system most sailors will run some form of cascade, with the most highly loaded systems normally being either the rig tension, vang or cunningham. As you move further away from the primary block in your cascade system the loads decrease dramatically so you would only ever need something like an XHL block if you’re using a purchase system of 32:1 or higher. This allows you to apply loads in the region of 500kg fairly easily.

If you’re only using a 16:1 or 24:1 purchase on your vang or rig tension system then using an XHL block would be over specified for the task but a HL block would be perfect for the first block used in the cascade, after this first block it’s only necessary to use our standard dynamic blocks.

Another consideration specifying your block is sheave size; while rope diameters have decreased the loads that are being applied to them certainly have not! While a 2.5mm Dyneema® may be capable of carrying the load with a breaking strain of around 600kg this doesn’t mean you can specify a 20mm diameter block such as the A2020 which only has a breaking load of 540kg.

If you’re performing a task that doesn’t need to move freely once it is in position, it is definitely worth considering using a plain bearing sheave. The ideal example of this is the mast head sheave for the main halyard, once you have hoisted the mainsail this sheave shouldn’t move at all so ball bearings would be unnecessary.

Alternatively, for high static loads or sheet deflectors our high load thimbles are a great maintenance free solution.